Do-Control Measures is the third step of the Model Sun Safety Program. In this step, the workplace implements control and prevention measures in response to the results of the risk assessments, particularly when the level of risk is not acceptable.

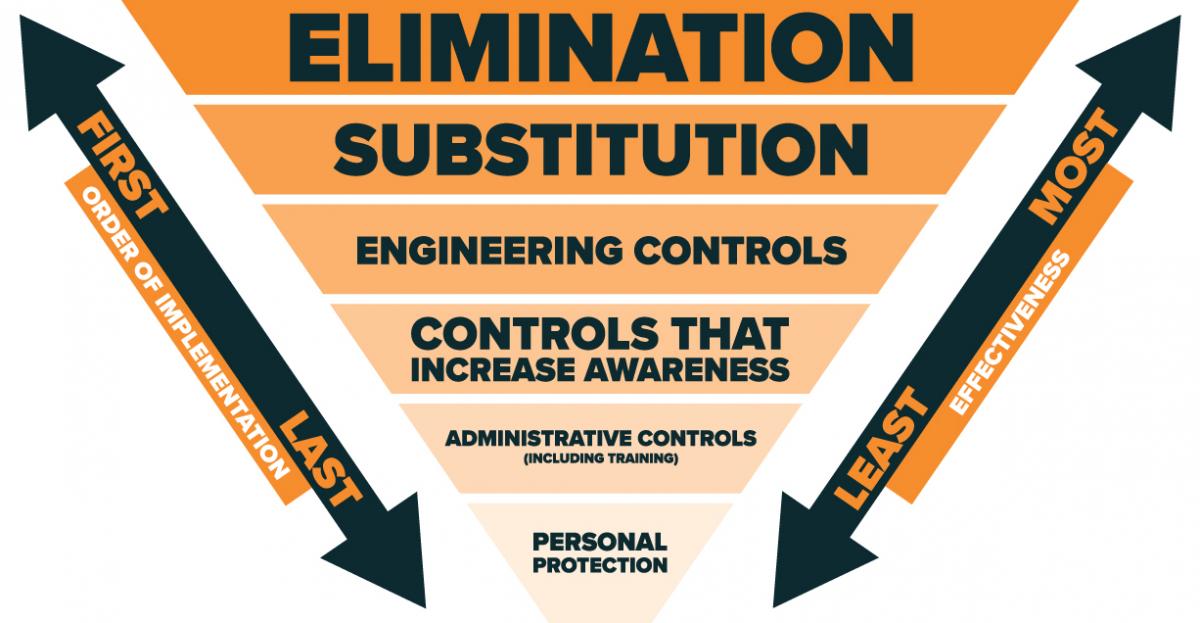

Our Model Sun Safety Program recommends control measures be implemented according to the hierarchy of risk controls. Controls are most effective when they address the hazard at its source; and are least effective when they address the hazard at the point of the worker. In many cases, it is necessary to use a combination of control measures in order to effectively manage the risk of a hazardous exposure.

Elimination or Substitution

For sun exposure of outdoor workers, the control measures of elimination and substitution are not possible. Following the hierarchy of risk controls, we are must then with use the less effective control measures.

Engineering Controls

Engineering controls separate the worker from the hazard by designing safety features into the work area, plant or equipment.

For controlling sun exposure, engineering controls include:

- Shade – where possible, workers should work in shade or take breaks in shade. Shade can either be human-made (for example, permanent and temporary shade structures) or natural shade from by trees.

- Reflective surfaces – in addition to direct exposure to solar UV radiation from the sun, worker exposure is also determined by the amount of reflected solar UV they receive. Reducing reflected solar UV by making surfaces less reflective is particularly important for eye exposure.

- Transmission through windows – window glass generally provides good protection against UVB radiation, but can transmit substantial amounts of UVA radiation. For workers who spend a lot of their time in vehicles, driving with the windows closed provides good protection from solar UV. Clear and tinted window films can be applied to windows for additional protection.

- Cooling systems – when workers are in a vehicle with the window closed, air conditioning is needed to minimize the risk of heat stress. For work tasks which involve a high level of physical activity, specialized cooling systems may be required to reduce the potential for heat stress.

Controls that Increase Awareness

When hazards are present, workplaces should improve workers ability to identify and detect the hazard. This includes warning systems (for example lights and alarms), warning signs, and other indicators that raise worker awareness of the hazard.

For sun exposure, signs and posters that list sun-safe practices can raise worker awareness of the hazard and remind workers about how to stay sun safe.

Administrative Controls (including training)

Administrative controls improve workers ability to safely interact with the hazard.

Work Practices and Procedures

For sun exposure, safe work practices are more likely than safe job procedures. For example, you could have daily procedures for supervisors to assess solar UV radiation risk and heat stress risk. Another example is to define when and how to use specific personal protection such as sunscreen or cooling vests.

‘Rules’ for Employees and Contractors

Rules need to apply to all workers and subcontractors, be simple and easily understood, and be easy to monitor and enforce by supervisors.

Examples of rules include: all incidents of negative health effects from sun exposure (for example, sunburn, photokeratitis, heat stress) need to be reported; or that all required sun safe personal protection needs to be worn or used at all times and according to sun safe work practices or supervisors directions.

Training and Education

A key role of the trainer is to empower workers to take a more active part in making their workplace safer.1 Training and education needs to help workers be aware of the risks of sun exposure, understand the safe work practices, procedures and rules, and have the knowledge and skills to protect themselves.

Training and education for sun safety should be incorporated into existing OHS training activities. For example, into new worker orientation, refresher training through safety talks, and the reinforcement of key sun safety messages and practices when there is an incident of over-exposure. We have developed a guide for using our training resources at your workplace, including tips and a sample training schedule.

Personal Protection

Control measures for personal protection include anything worn or used by an individual worker to provide protection to themselves. Personal protection is the last line of defense. It should be only used when other control measures are not possible or have not provided sufficient protection.

Personal protection for sun exposure should provide coverage to as much of the workers body as possible, yet still allowing workers to stay cool during hot weather. Sun safe personal protection measures include:

Clothing: This is the most effective form of personal protection. Wear long sleeved shirts with collars and long pants. Choose breathable fabrics with a high ultraviolet protection factor (UPF).

Hats and hard hats: Choose a broad brimmed hats and legionnaire style hats for the most protection. Baseball style caps provide good protection to the nose, but little protection to the cheek and chin, and no protection to the ears or neck.

Sunglasses and protective eyewear: Our eyes are very sensitive to UV radiation and so all outdoor workers should wear ear protection all year round. For workers who do not require ‘protective eyewear’ as described in CSA Z94.3.1-09, good quality sunglasses will provide excellent UV protection, particularly if they are close-fitting and wrap-around in design.

Sunscreen: Choose a broad spectrum, water resistant sun screen with a minimum sun protection factor (SPF) of 30. Sunscreen is the least favorable of the personal protection measures for outdoor workers. A list of sunscreens recognized by the Canadian Dermatology Association are available on their website.

Cooling wear: Cooling wear is available to provide additional cooling for workers. This includes vests, neck shades, towels, headwear and bandanas which either work on the principle of evaporative cooling or use in-built replaceable ice/cooling packs. Some of these are designed to be used with hard hats.

Control Verification and Validation

Verification is the process of checking that the risk controls have been implemented. Validation is the process of checking that the controls are effective in reducing risk.2 This can include physical inspection of the workplace for sun safety measures, observation of worker sun safe practices, measurement of worker exposure levels, tracking of sun exposure incidents and employee feedback.

Build Your Own Program Tips:

Worker buy-in

It is important to get worker buy-in and acceptance of the control measures to be enhanced or implemented. This can be through:

- Starting with ‘easy wins’, such as adding sun safety education and training

- Considering ways to include all staff in activities, especially those who work in remote locations

- Planning a launch for the sun safety program

- Including workers in the decision-making for what personal protection to buy and having a selection of PPE for workers to choose from

- Being proactive about any negative perceptions which the public or other stakeholders may have (for example, worker rest breaks as part of enhanced work-rest regime for heat stress)

The next step in the Model Sun Safety Program is Step 4: Do-Support

Go back to Step 2: Plan

- 1. Worker Education and Training, in: ILO Encyclopaedia of Occupational Health and Safety. http://www.iloencyclopaedia.org/component/k2/item/90-worker-education-and-training

- 2. CSA Z1002-12 – Occupational health and safety – Hazard identification and elimination and risk assessment and control. (2014). CSA Group.